Inside the Key Features of Advanced Warehouse Automation Software

Chosen theme: Key Features of Advanced Warehouse Automation Software. Step into a modern warehouse where real-time visibility, smart orchestration, and resilient systems turn complexity into momentum. In this home page deep dive, we explore the capabilities that keep inventory honest, robots coordinated, and people empowered. Share your challenges at the end of each section and subscribe to follow our next feature breakdowns.

Robot and Workflow Orchestration: From AMRs to Goods-to-Person

The engine evaluates battery levels, traffic, congestion heatmaps, and task urgency to dispatch AMRs and people efficiently. It enforces safe passing rules and dynamic speed limits, turning chaotic peaks into controlled flow while still hitting service-level promises.

AI-Driven Optimization: Slotting, Labor, and Demand Foresight

Dynamic slotting that adapts to seasons and promotions

The software continuously re-ranks SKUs by velocity, affinity, cube, and handling constraints, then proposes moves that cut travel without disrupting stability. A beverage distributor reduced pick travel by 21% when AI grouped correlated flavors that buyers often order together.

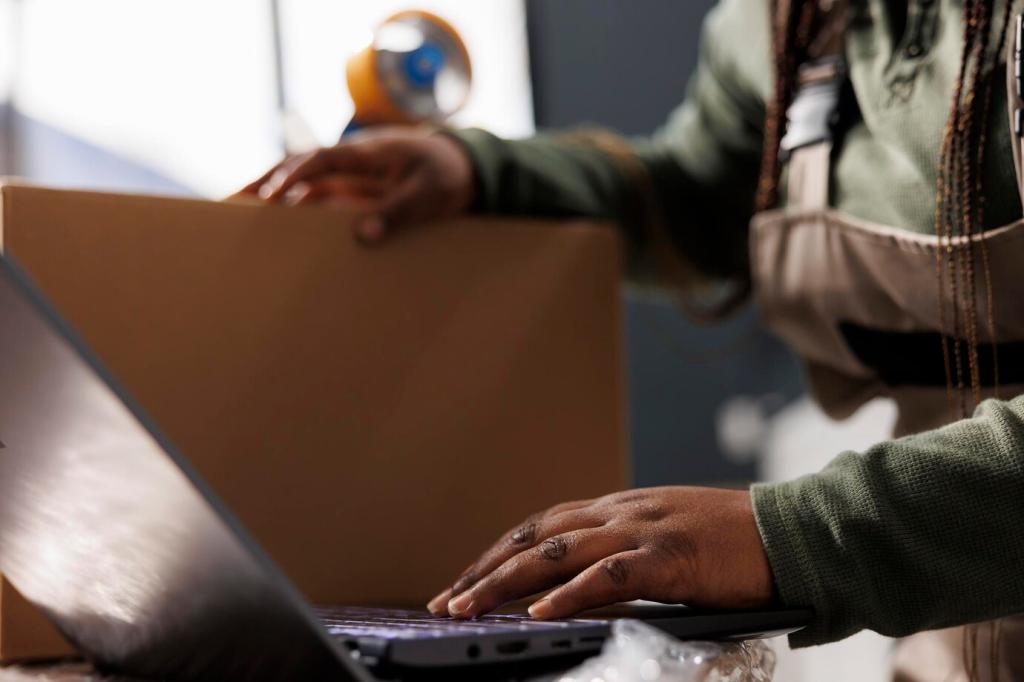

Labor optimization that respects human rhythms

Shift planners use fatigue-aware pacing, cross-training matrices, and real-time productivity to assign work that is achievable and fair. This keeps throughput high while improving retention, because great software optimizes people without treating them like machines.

Engage: Which SKU surprises you most?

Share a product whose demand pattern defied expectations. We’ll analyze common signals that predict similar swings and post a downloadable checklist to catch the next spike early.

Seamless Integration: WMS, ERP, PLCs, and Cloud APIs

Instead of batch files, the platform streams events—receipts, picks, moves, and exceptions—so decisions update the moment conditions change. Webhooks trigger label prints, replenishment, or quality holds with zero manual coordination and fewer timing errors.

Seamless Integration: WMS, ERP, PLCs, and Cloud APIs

Prebuilt drivers and PLC mappings reduce commissioning time and risk. Teams can bring new stations online in hours, not weeks, while maintaining strict version control and rollback plans for safe, predictable updates.

Analytics, Dashboards, and Digital Twins

01

Operational KPIs that matter minute by minute

Dashboards surface backlog, pick rates, dock utilization, and aging exceptions with drill-downs to station and associate. Alerts flag trends before they become outages, allowing supervisors to course-correct with data, not hunches.

02

Simulation and digital twins for risk-free experimentation

Clone your floor in software to test new batching rules, station layouts, or AMR fleet sizes. A 3PL used a twin to validate wave-to-waveless transition before peak, unlocking 14% higher throughput without overtime shock.

03

Engage: What would you simulate first?

Tell us which scenario you want to trial—pick module redesign, buffer sizing, or new packaging flows. We’ll publish a starter scenario with metrics and acceptance thresholds you can reuse.

Compliance, Safety, and Traceability by Design

Automated audit trails and lot/serial lineage

From receipt to ship confirmation, the system stamps user, device, time, and location, creating an immutable chain of custody. Recalls become targeted and fast, reducing waste and brand risk when minutes matter.

Safety interlocks and zone control across mixed fleets

The software enforces keep-out zones, speed controls, and light curtain logic for humans working beside AMRs and conveyors. Collision avoidance and lockout procedures are baked into workflows, not taped to a wall.

Engage: How do you prove compliance under pressure?

Share the documentation sprint you dread most—annual audits, customer scorecards, or trace tests. We’ll compile a compliance checklist and export template aligned to these features.

Scalability, Resilience, and Configurability

Each service—task assignment, label generation, slotting—scales independently, so a rush on packing does not starve receiving or replenishment. Elastic cloud capacity keeps latency steady as order lines climb.

Scalability, Resilience, and Configurability

If networks hiccup, handhelds cache tasks and resync. When a station fails, routing rules bypass it automatically. You keep shipping, collecting data, and closing the loop without panic or ad hoc workarounds.