People at the Center: Collaboration and Safety

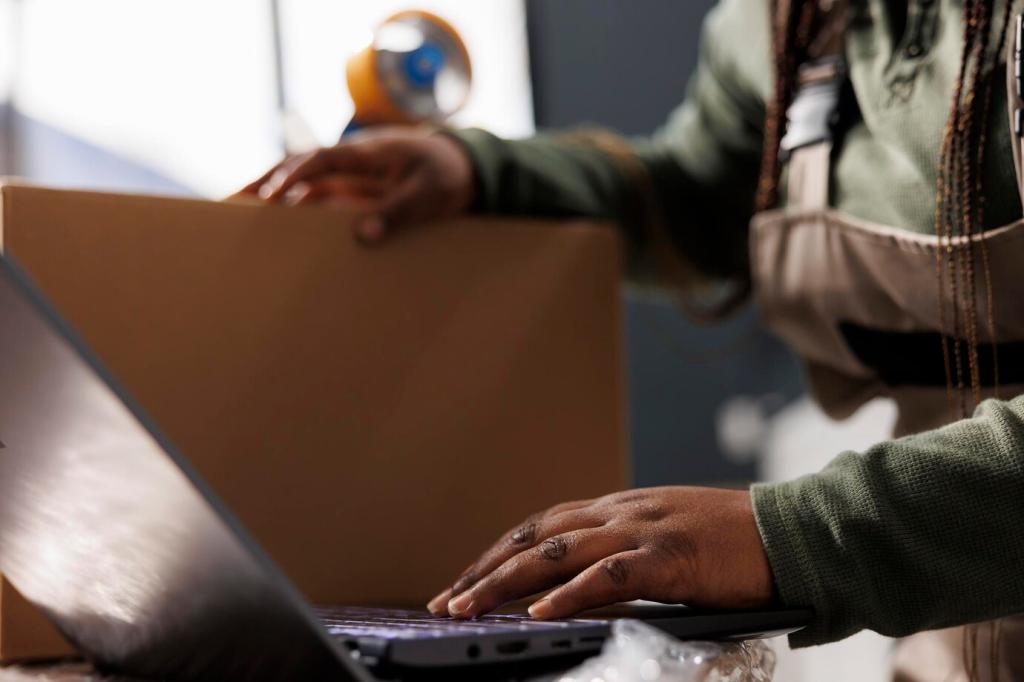

Robots reduce walking and heavy lifting, while associates oversee exceptions and quality. Maya, a veteran picker, moved into a flow lead role and now coaches continuous improvements. How would you redesign roles to unlock creativity and reduce fatigue?

People at the Center: Collaboration and Safety

Microlearning, buddy systems, and visual SOPs help teams master new tools confidently. Short daily huddles surface issues early. Tell us what training formats resonate in your warehouse, and we will share templates readers can adapt tomorrow.

People at the Center: Collaboration and Safety

Speed limits, geofencing, and redundant sensors keep humans and robots in harmony. Clear floor markings and alert cues prevent surprises. Share your safety wins or worries, and we will compile a crowd-sourced checklist for safer automation rollouts.

People at the Center: Collaboration and Safety

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.